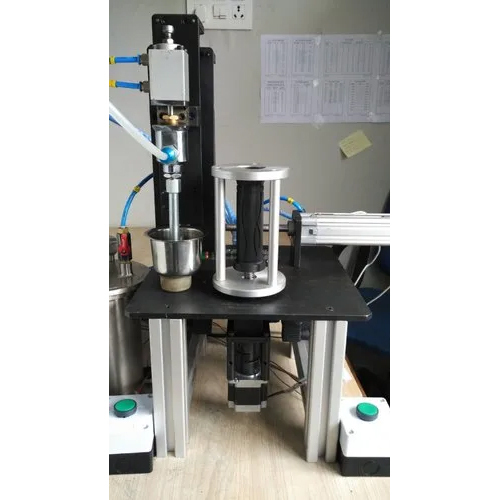

Two Head X-Y Table with Vacuum Chamber Dispensing Machine

Price 950000.0 INR/ Number

Two Head X-Y Table with Vacuum Chamber Dispensing Machine Specification

- Product Type

- Vacuum Chamber Dispensing Machine

- General Use

- Industrial

- Material

- Stainless Steel

- Type

- Vacuum Chamber Dispensing Machine

- Computerized

- No

- Automatic

- Yes

- Control System

- Semi Automatic

Two Head X-Y Table with Vacuum Chamber Dispensing Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 10 Week

- Sample Available

- No

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Two Head X-Y Table with Vacuum Chamber Dispensing Machine

TWO HEAD X-Y TABLE WITH VACUUM CHAMBER DISPENSING MACHINE:

A Two-Head X-Y Table with Vacuum Chamber Dispensing Machine is a precision automation system used in manufacturing and electronics for accurate material dispensing (such as adhesives, solder paste, or other fluids) in controlled environments.

FEATURES:

Mix Ratio: Fixed ratios from 1:1 to 1:10, adjustable via screw/gear pump.

Dispensing Control: Volumetric shot control with cycle status indication.

Mixing: Static and dynamic mixing with electric actuator.

Degassing: Removes air bubbles from tank and dispensed material.

Operation: Low-voltage, electronically controlled pneumatic system.

Automation: Fully interlocked PLC & HMI with automatic metering.

Compatibility: Works with various external fluid reservoirs.

Valves: Two-way positive flow valves for accurate ratio control.

External Valve Interface: Supports remote valve operation.

SPECIFICATIONS:

Mix Ratio: 1:1 to 1:10 (adjustable)

Tank Size: 15200L (customizable)

Shot Size: 0.55g / 550g

Flow Rate: Variable with shot size

Weight: 200800 kg (approx.)

Dimensions: 2500 1200 1500 mm (LWH)

Operation: Low-voltage pneumatic, electronically controlled

Control: PLC + HMI, automatic metering

X-Y Table: Servo-driven (300300 / 600600 mm)

Purge System: Full-volume purge without volume loss

Shot Control: Volumetric with cycle status display.

APPLICATIONS:

1.Automotive Industry:

Heat sinks, battery packs, engine components, power electronics, Hybrid & electric vehicles (EVs)

Gear shift sensors, GPS tracking sensors, RR units, magneto coils, diode assemblies

2.Electronics & Electrical:

PCBs, smart devices (smartphones, tablets), household appliances

Entertainment electronics, connectors, relays, switches

3.Medical Devices:

Encapsulation of sensors, pumps, diagnostics components

Adhesive dispensing for medical device assembly

4.Industrial & General Manufacturing:

Filter potting, coil embedding, LED module sealing

Electrical insulation and sealing in harsh environments

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dispensing Machine Category

Asphalt Potting Machine

Price 950000.00 INR / Unit

Minimum Order Quantity : 1 Number

Voltage : 430 VAC,3ph,50Hz Volt (v)

Warranty : Yes

Automatic : No

Control System : Semi Automatic

RTV Silicone Sealant Dispensing Robotic Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Warranty : Yes

Automatic : No

Control System : Manual

Digital Alpha Dispenser

Price 45000.00 INR / Unit

Minimum Order Quantity : 1 Number

Voltage : 220 VAC Volt (v)

Warranty : 24 Months

Automatic : No

Control System : Manual

Adhesive Handle Grip Dispensing Machine

Price 110500.00 INR / Unit

Minimum Order Quantity : 1 Number

Voltage : 230VAC Volt (v)

Warranty : Yes

Automatic : Yes

Control System : Full Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free